Underground comprehensive pipe gallery escort urban public cases

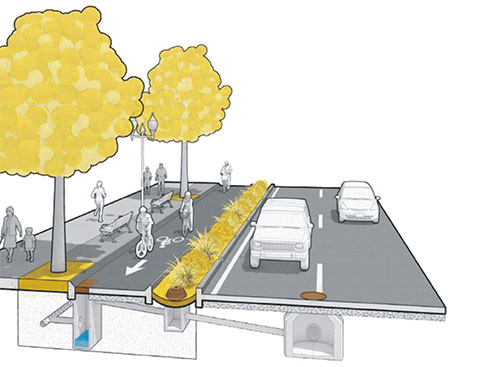

The comprehensive platform pipeline corridor, also known as the underground urban pipeline comprehensive corridor. It is the construction of an intensive tunnel space underground on urban roads,

Integrating various pipelines such as municipal, power, communication, gas, water supply and drainage, and heating,

And it is equipped with maintenance ports, ventilation ports, lifting ports, monitoring and control systems, etc,

Implement unified planning, design, construction, and management to achieve the full utilization and resource sharing of underground space.

Current situation of comprehensive pipe gallery engineering in China

At present, China's municipal comprehensive pipe gallery engineering mainly adopts two methods: on-site pouring and fully prefabricated assembly

Cast-in-situ pipe gallery

All processes are completed on site/with good integrity/with high construction difficulty/long operation time

Large on-site workload/low efficiency, high cost/high labor demand during construction process, high dependence on skilled workers/difficult to control quality and progress

Fully prefabricated prefabricated comprehensive pipe gallery

Only suitable for small-scale pipe galleries/less on-site construction labor/fewer construction processes

High mold manufacturing cost/weak adaptability/heavy construction machinery with multiple assembly nodes/poor waterproof performance

Shun'an Yuanda Technology System Stacked Assembly Integrated Pipe Gallery

Equivalent to cast-in-place, it not only integrates the characteristics of good overall cast-in-place, but also leverages the advantages of prefabricated assembly to simplify on-site construction processes.

Produce

◆ Flexible intelligent production line

◆ Suitable for various sizes and types of pipe galleries

◆ High production efficiency and low cost

Transport

◆ Convenient transportation

◆ High efficiency

◆ Low cost

Construction

◆ Simple and easy to operate construction

◆ Controllable construction quality

| Quality | Structural safety quality | Prefabricated lamination is equivalent to cast-in-place, with good structural safety |

| Waterproof quality | Component factory production, combined with cast-in-place, with good waterproof performance | |

| Transport | Small component weight, high transportation efficiency, and low cost | |

| Product specifications | Any size product | |

| Energy saving and emission reduction | Good energy-saving and emission reduction effect | |

| Cost (four warehouses) | Template(m2) | 0 |

| Scaffold(m2) | 0 | |

| Number of workers | 25 | |

| Cost estimation for standard section of 24 meters | 1 million 200 thousand | |

| Schedule | Standard section 24 meter construction period (days) | 5 |

0086-312-7615200

0086-312-7615200