Digital simulation enables optimized resource allocation, intelligent control enables full process traceability

Intelligent platform

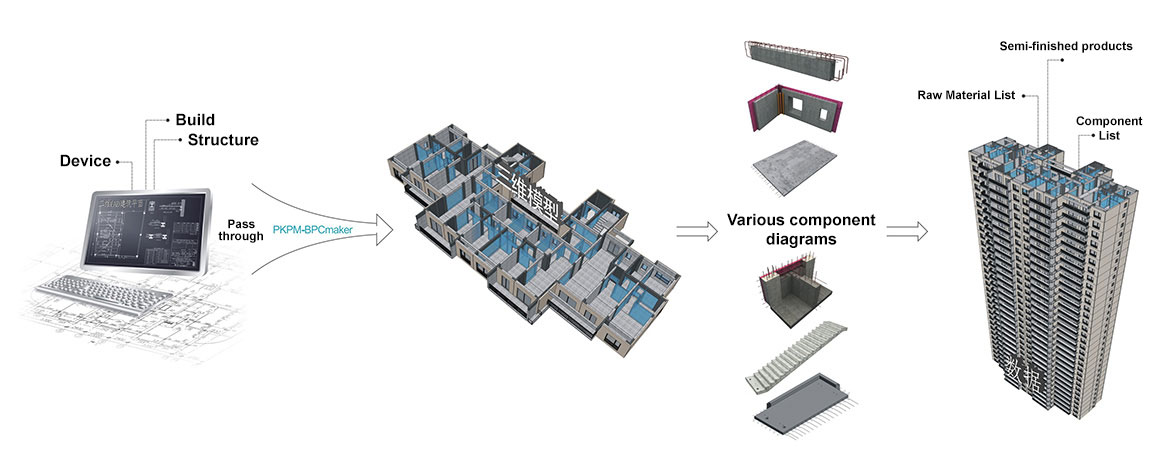

Intelligent manufacturing is first reflected in the optimization of intelligent software. In the deepening stage of the project, through the self-developed BIM software application, detailed drawings and bill of materials can be directly exported; Through the one thing one code system, the entire production process is controlled to achieve traceability of materials and production conditions.

Intelligent design

Flexible Manufacturing+Data Driven Transform from traditional production to flexible and intelligent production.

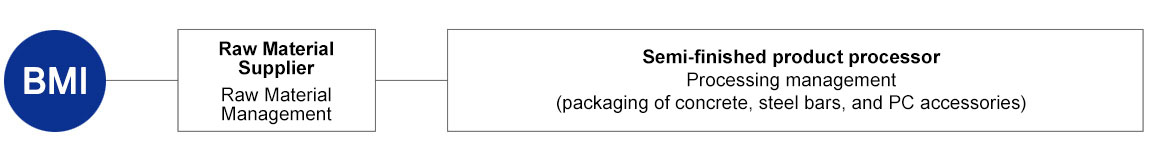

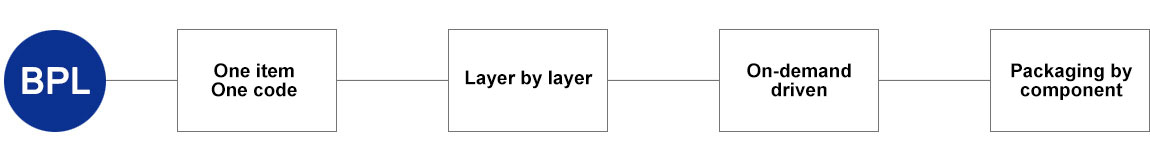

Segmental management of BMI+BPL precast concrete component (PC) production

BMI: Joint inventory management to simplify and optimize the operational process of supply chain inventory management. While reducing logistics links and logistics costs, partially eliminating inventory fluctuations caused by uncertainty and distorted demand information between supply chain links, improving the overall efficiency of the supply chain. Create conditions for continuous replenishment, rapid response, and on-time supply chain operations.

BPL: Implement a data-driven full process management mode from factory to construction site based on one thing, one code. To provide the necessary data analysis for management, the operators scan the code to schedule the plan, transmit the data to the system backend, and the system automatically generates various production data analysis such as output, efficiency, rhythm, and quality.

0086-312-7615200

0086-312-7615200