We practice green buildings, significantly improving economic, social, and environmental benefits

We Practice Green Buildings to Truly Realize Five Energy Conservation and One Environmental Protection

Save 80% water

The prefabricated components are completed in the factory, which is different from the traditional bricklayer construction mode of "dry method building", and there is no water required for wet operation and concrete curing on site;

Energy saving 70%

The closed factory production method can achieve centralized production with low comprehensive energy consumption; The construction personnel on the project site are saved compared to traditional cast-in-place methods; The main construction eliminates insulation and secondary structures, reducing the use of on-site formwork;

Hour 60%

Industrialization has significantly increased labor productivity, requiring only one-third of the construction cycle compared to traditional construction methods;

Material saving 20%

Factory scale production, optimized integration, CNC processing of steel bars, precise pouring and tamping of concrete, to minimize material loss as much as possible;

Land saving 20%

Plastering the interior and exterior walls of the building effectively increases the usable area, achieves equivalent functionality in a smaller area, and improves land use efficiency;

Low carbon and environmental protection

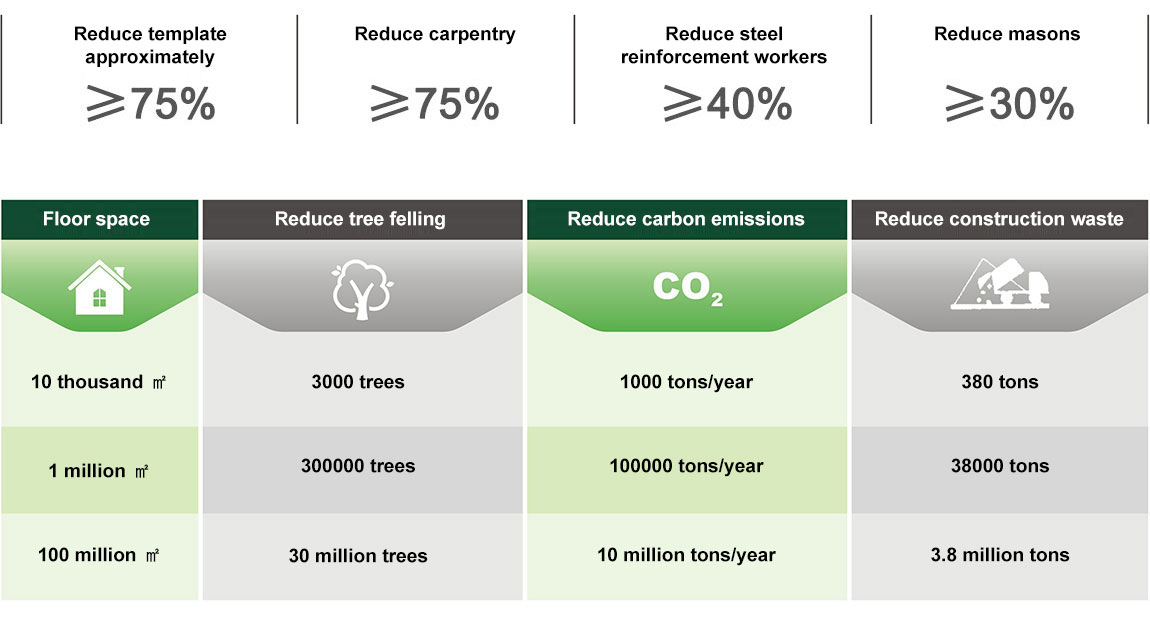

Factory manufacturing, greatly reducing on-site operations, without dust, noise, and sewage pollution; Improve the environmental protection technology level of industrial equipment; Centralized decoration without a large amount of construction waste pollution during the second decoration; Each hundred square meters of construction area can reduce the generation of approximately five tons of construction waste; Simultaneously reducing the destruction of forest land; All products use environmentally friendly materials; Factory exhaust materials and sewage can be recycled for secondary use, truly achieving green and environmental protection throughout the entire process of building industrialization.

We achieve five major changes and three major controllability through industrial production methods

Five Major Transformations/Handicrafts - Mechanical Construction Sites - Factory Construction - Final Assembly Migrant Workers - Industrial Workers, Technical Workers - Operators

Three controllable/quality controllable progress controllable cost controllable

Comparison Table of Main Differences between Industrialization and Traditional Construction of Shun'an Yuanda Building

Environmental protection control throughout the entire industrial chain

Upstream industrial chain control

1. Rely on local county resources, use local materials, and pay attention to the maintenance of the ecological environment.

2. Establishing an upstream raw material company and conducting mining and production in accordance with government requirements for legal compliance and environmental protection is beneficial for the overall environmental control of upstream raw materials.

3. Strictly follow the provisions of the Air Pollution Prevention and Control Law, Road Traffic Safety Law, and Road Transport Regulations during transportation to ensure safe transportation.

Environmental control of production process and lifting

Production control:

A fully enclosed factory building, a fully enclosed raw material yard, a fully enclosed finished product storage yard, a fully enclosed mixing center, and a dust-free production management system.

Transportation control:

The precast concrete components that meet the delivery conditions have been cured, and transportation vehicles must be cleaned and flushed before entering and leaving the workshop and construction site.

Hoisting control:

Safety, high efficiency, dry installation, and controllable management.

0086-312-7615200

0086-312-7615200